HOW DESIGN THINKING HELPS YOU TO UNDERSTAND YOUR CUSTOMER

Page 92

CONNECT TO BETTER

WAVIN LOVES PLUMBERS

I COULDN'T BELIEVE BUILDING YET ANOTHER FACTORY WOULD HELP US IMPROVE BUSINESS RESULTS. I WANTED TO EXPLORE MORE OPTIONS EVEN IF IT MEANT GOING AGAINST THE GRAIN.

Richard van Delden

Executive Director, Supply

Chain & Operations

Wavin, a large manufacturer (b2b) of plastic pipes used mainly for drainage and water supply purposes, had a strong position for years in the Turkish market. In 2013 the company’s market share dropped, moving it out of the top 3. Wavin’s plastic pipes were perceived as commodities and competition was based only on price. The CEO asked: How can we regain our position as a well-known market leader?

Page 93

|

• | August 2013: Wavin wanted to become the leader in the Turkish market. The local management team took on the assignment to come up with a plan. A business plan. |

|

• | September 2013: Wavin wanted to build a factory near Instanbul. The current factory in Andana was far away from Turkey’s most populated city, Istanbul. It was thought that a new factory in Istanbul would get Wavin back on track. |

| • | October 2013: An internal memo from the CEO starting to focus on the customer. | |

|

• | Talking to a plumber in the street, Richard realized that no plumber is familiar with the Wavin brand. |

|

• | October 2013: Sanity check! If Wavin was to understand its customer and their job-to-be-done, could that info be used to create more options to grow their market share? |

|

• | Get out of the building. A special Wavin team went on safari to visit construction sites. Observe and learn what plumbers and installers are dealing with. |

|

• | January 2014: Wavin realized that mechanical contractors were not their customers. They could not offer a value proposition to them. But that could mean a world of difference for plumbers. |

|

• | Finally, the hard decision was made to cancel construction of the factory altogether, since it would not help them reach their goal. This meant a lot of disappointment for team members who were involved drawing up plans for the factory. |

|

• | June 2014: Wavin opened their (first) academy in Turkey. Now that they have proof of concept, they know who their real customer is and how to create value (with their customer). Wavin is ready to scale the academy to other locations. |

LET’S BUILD A FACTORY!

Given the CEO’s challenge, the sales team crunched some numbers and came up with what they believed to be a viable solution: build a new factory. From the sales team’s perspective, building a new factory to manufacture pipes closer to the growing market in Istanbul would enable the company to compete on price. To help support its point, the sales team submitted a business plan to the CFO as well as Richard. The race was on to get it done.

MORE CAPACITY? REALLY?

Page 94

Richard van Delden: When I first saw the business plan for the €60M factory, I was shocked. I was handed a detailed description of how a factory built in Istanbul could produce and sell pipes at a lower price. With enough production capacity nearby, would another factory really help us to regain market share? How will this option affect our margin? Sales was convinced they needed to be able to produce close to the main market and have stock on hand. “Our customers want products now at the lowest price possible!” I wanted to explore other options. Most of all, I wanted to understand what our customers were buying and why.

WE DON’T KNOW OUR CUSTOMER

Richard: One day while parking my car in Amsterdam I came across a construction site where I saw Wavin products. I sparked up a conversation with one of the plumbing contractors onsite, who stated: “My clients want the best quality, but they don’t know Wavin.” A light bulb went off in my head: “We don’t know our customers!”

SANITY CHECK

Richard and the CFO Andres Capdepon made the bold decision to first understand what their customers really wanted and needed before making a decision about what to do next.

SAFARI

To learn from their customers, a team of Wavin Turkey employees, as well as Richard and Andres, visited construction sites where they could observe customers in their natural (work) habitats. The team gathered lots of great insights during their week of visits. Together they learned that there was a huge difference in the quality delivered by plumbers onsite due to misuse of equipment and materials. The team also learned that distributors loved the in-store branding. And, just as important, distributors do more than sell and distribute pipes. They also play an important social role in connecting plumbers. As the team asked more questions of the plumbers, contractors, and distributors, they uncovered hidden knowledge – which prompted even more questions.

Page 95

A-HA! (NOT THE CUSTOMERS YOU THINK THEY ARE!)

After the site visits, some of the customers were invited to a local hotel in Istanbul to meet the project team and to provide feedback on various ideas generated by the team. The plumbers were really interested in everything that Wavin could do to help them do a better job and deliver higher-quality results. The team’s most important discovery was that the plumbers wanted professional how-to videos, product manuals, and direct connections with Wavin experts even more than they wanted lower prices. Providing these services would make Wavin competitive and deliver better-quality results to their customers. This was a real a-ha moment for the Wavin team. They used this insight to design a new community-driven approach: they would help their customers become better plumbers by sharing knowledge (and tea) with each other. This approach turned into the (free) Wavin Academy.

SHARING KNOWLEDGE

The first prototypes of the Wavin Academy proved a success. As such, the project team decided to build the Wavin Academy on the production site in Adana, Turkey. The center opened a few months later, in June 2014. “At the moment more than 7,000 people have visited the academy (see Facebook page),” Orhun said. “When I joined the Turkish team, I knew this was the way to better engage with our customers. We teach them, we learn from them, and we build better relationships in ways that a factory would not. In short, we’ve become important to our customers – and they to us – in ways that we never knew were possible.”

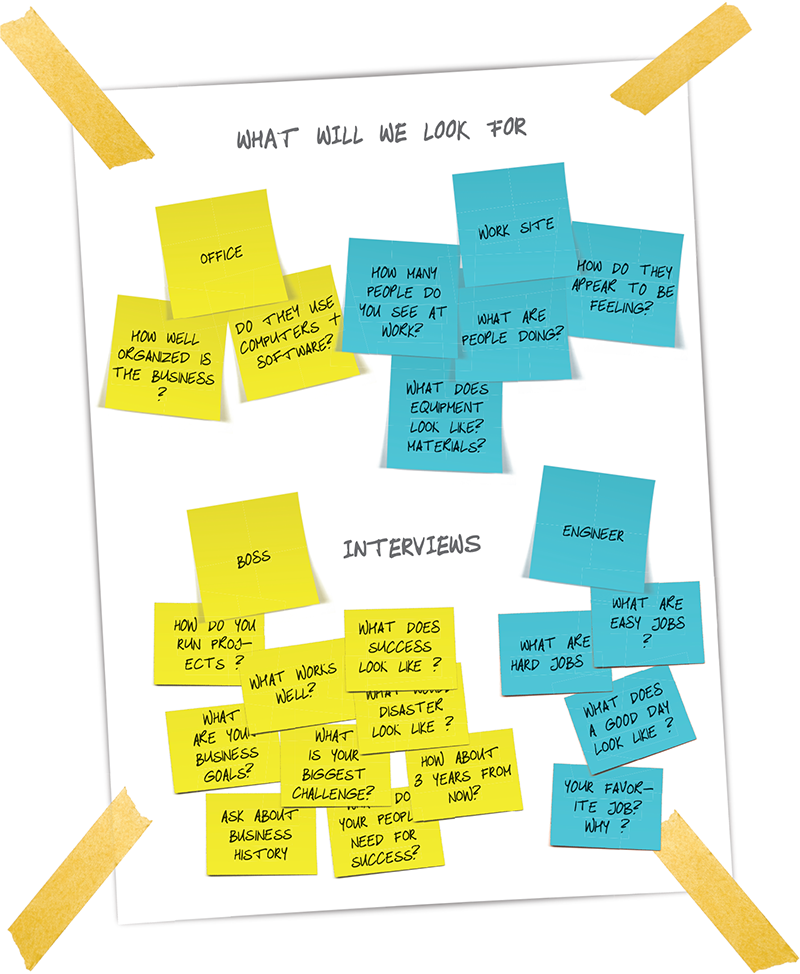

An example of sketch notes made during the observation and the interview.

Page 96

WAVIN DISCOVERING A NEW FUTURE

THE MORAL OF THIS STORY IS …

Richard: While the factory may certainly have been one good option to grow our Turkish market share, we realized that the business plan for the factory was based on assumptions about the market and our customers’ jobs, needs, and wants. We knew that there were other options worth exploring as well. So, rather than spend time arguing about the one option on the table, we decided to first validate our assumptions and learn from our customers first hand. We got out of the building.

By doing this ourselves we learned more than we would if we had simply hired a firm to do a market study for us. In meeting our customers on their turf, we uncovered hidden context and meaning and came up with new questions based on what we learned. The answers to these questions, of course, led to further insights about our customers and the commercial plumbing market in Turkey. We also built lasting relationships with the people who install and use our products.

At the end of the day we invested a few hundred thousand dollars in the first Wavin Academy instead of the tens of millions of dollars we were prepared to pour into a factory. We now have a distribution center in Istanbul, which is closer to our customers. And, with the Wavin Academy, we have a brick-and-mortar space where we can interact with our customers and which ultimately helps to strengthen the Wavin brand in their minds. Design thinking is at the heart of our business now. ![]()

Page 97

The brand-new Wavin Academy in Turkey. This was such a success that it is the model for all future Wavin Academies to open worldwide.

PLUMBERS LOVED THAT WAVIN COULD HELP THEM DO A BETTER JOB.