Case-Study Application II: ARIPAR-GIS

Abstract

This chapter demonstrates the detailed quantitative analysis of Natech risk by applying the ARIPAR-GIS software introduced in Chapter 9 to two case studies. Case study 1 analyzes earthquake-induced Natech risks at a hazardous facility and case study 2 studies the impact of floods. Individual and societal risk were calculated and compared to the risk levels obtained without considering Natech scenarios. The results confirm the significant influence that Natech risks may have on the overall risk at a hazardous installation.

Keywords

11.1. Introduction

11.2. Case study 1: Natech Scenarios Triggered by Earthquakes

Table 11.1

Probit Functions for Human Vulnerability Used in the Case Studies (Mannan, 2005; van den Bosch et al., 1992)

| Scenario | Target | Probit Equation | Dose, D | Dose Units |

| Radiation | Human | Y = −14.9 + 2.56 ln(D) | I1.33·te | I: kW/m2 te: s |

| Overpressure | Human | Y = 1.47 + 1.37 ln(D) | ps | ps: psig |

| Toxic release: NH3 | Human | Y = −9.82 + 0.71 ln(D) | C2∙te | C: ppm te: min |

Y, probit value; I, radiation intensity; ps, peak static overpressure; C, toxic concentration, te, exposure time.

(A) LSIR contours (events/year), (B) societal risk with (solid lines) and without (dashed lines) the consideration of possible accident scenarios due to earthquake impact. The impact of anchoring tanks as a safety measure is also shown. Adapted from Antonioni et al. (2007).

11.3. Case study 2: Natech Scenarios Triggered by Floods

11.3.1. Layout and Vessel Features

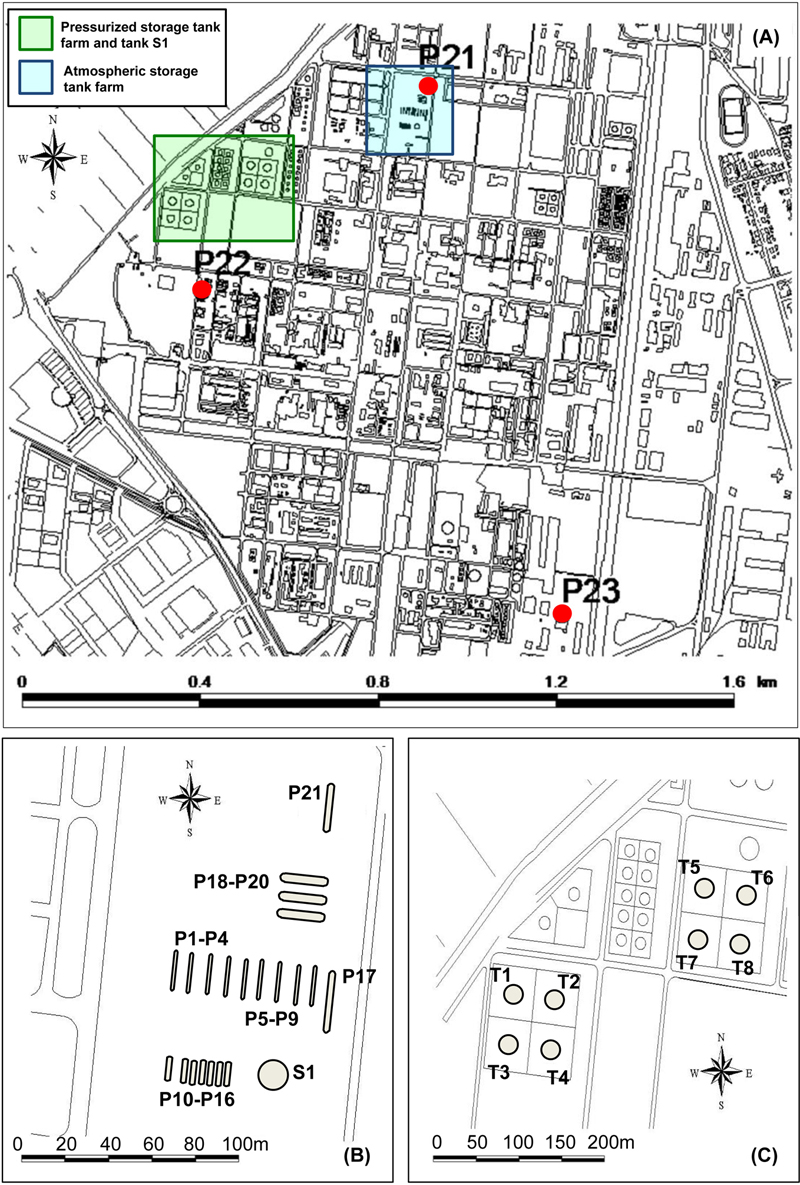

(A) Overview of the industrial area, position of the tank farms, and location of pressurized tanks P21–P23; (B) pressurized tank farm and storage tank S1; (C) atmospheric tank farm.

Table 11.2

Main Features of the Vessels Considered in Case Study 2 With Ambient Temperature 293 K

| Vessel Features | Pressurized Vessels | Atmospheric Vessels | ||||||

| P1–P9 | P10–P16 | P17 | P18–P20 | P21–P23 | S1 | T1–T4 | T5–T8 | |

| Nominal capacity (m3) | 50 | 30 | 115 | 150 | 100 | 3179 | 6511 | 6511 |

| Diameter (m) | 2.7 | 2.4 | 2.75 | 3.2 | 2.8 | 15 | 24 | 24 |

| Lengtha /heightb (m) | 10 | 6.5 | 20.1 | 19.4 | 18 | 18 | 14.4 | 14.4 |

| Shell thickness (mm) | 23 | 21 | 24 | 27 | 24 | 12.5 | 12.5 | 12.5 |

| Vessel tare weight (metric ton) | 12.3 | 5.9 | 29.2 | 36.1 | 26.2 | 110 | 165 | 165 |

| Saddle parameter (m) | 1.48 | 1.38 | 1.58 | 1.78 | 1.58 | — | — | — |

| Filling level | 90% | 90% | 90% | 90% | 90% | 75% | 75% | 75% |

| Substance contained | Propylene | Propane | LPGc | Ammonia | Chlorine | Organic solvent | Gasoline | Benzene |

| Physical state | Liquefied gas | Liquefied gas | Liquefied gas | Liquefied gas | Liquefied gas | Liquid | Liquid | Liquid |

| Pressure (bar) | 8 | 8.5 | 2 | 8.5 | 6.7 | 1.05 | 1.05 | 1.05 |

| Liquid density (kg/m3) | 615 | 450 | 550 | 600 | 1400 | 650 | 750 | 877 |

| Vapor density (kg/m3) | 13.8 | 15.4 | 4.8 | 4.9 | 19.3 | 0.97d | 0.97d | 0.97d |

| Inventory (metric ton) | 32 | 12 | 59 | 84 | 140 | 1550 | 3656 | 4275 |

Adapted from Antonioni et al. (2015).

a Horizontal vessel.

b Vertical vessel.

c Assumed as pure butane.

d Average density of the purge gas (e.g., nitrogen blanketing), not relevant for model application

11.3.2. Workers and Surrounding Population

11.3.3. Flood Scenarios

Table 11.3

Flood Reference Scenarios Defined for Case Study 2

| Flood Conditions | Return Time (Year) | Flood Frequency (1/Year) | Flood Depth (m) | Flood Velocity (m/s) |

| Scenario 1 | 500 | 2.0 × 10−3 | 2.00 | 0.5 |

| Scenario 2 | 500 | 2.0 × 10−3 | 0.50 | 2 |

| Scenario 3 | 200 | 5.0 × 10−3 | 1.15 | 0.75 |

| Scenario 4 | 30 | 3.33 × 10−2 | 0.75 | 0.5 |

Adapted from Antonioni et al. (2015).

11.3.4. Individual and Societal Risk Calculated for Conventional Scenarios

Table 11.4

End-Point Scenarios Considered for the QRA of Internal Release Events at a Hazardous Facility

| Tank ID | Loss of Containment Event | Final Outcome | Frequency (1/Year) |

| T1–T8 and S1 | Instantaneous release into the catch basin of the total inventory | Pool fire | 4.5 × 10−6 |

| P1–P17 | Release in 10 min of the total inventory | Flash fire of propane, propylene, or LPG | 4.5 × 10−7 |

| P18–P23 | Release in 10 min of the total inventory | Toxic cloud of ammonia or chlorine | 5.0 × 10−7 |

Adapted from Antonioni et al. (2015).

11.3.5. Individual and Societal Risk Including Flood-Induced Scenarios

(A) Flood scenario 1, (B) flood scenario 2, (C) flood scenario 3, (D) flood scenario 4. From Antonioni et al. (2015).